Application of Membrane Structure in Sewage Treatment Plant

Date:2015.4.3 Hit:9030

Due to the acceleration of urbanization, more and more sewage treatment plants built in the suburbs have been brought into the periphery of urban construction.

A considerable number of anaerobic pools, sludge concentration pools and biological flocculation pools of sewage treatment plants are built around residential areas and factories. The environment, features and odor of sewage pools directly affect people's work, life and health.

Stench gas diffuse affect people's lives;

——for sewage pool odor treatment is imperative!!

Waste Gas Collection-Several Methods for Deodorization and Covering of Sewage Tanks: Common Carbon Steel Framework + Sunshine Plate:

Stainless steel skeleton + FRP

Common Carbon Steel+Film Structure

Plain carbon seel+membrane structure

1 stainless steel skeleton + fiberglass reinforced plastics 2 ordinary carbon steel skeleton + sunshine plate is also very good in sealing performance. The limitation is that when the span is large (4-8 meters), the cost of the built-in steel skeleton will increase correspondingly and its maximum span is usually not more than 8 meters.

The steel supporting parts of the above-mentioned 1 and 2 structures are inevitably placed inside the roof. Because the concentration of corrosive gases in the roof of the pool is doubled after adding the cover, the temperature is very high under the sunlight radiation, and the inner steel structure is very easy to corrode. The general service life is 2-3 years, that is to say, it will face the secondary construction of the whole structure in a short time. Practice has proved that even if stainless steel is used in steel structure, its durability in corrosive environment is still not guaranteed, and the cost is very high.

Brittle Cracking of Sunshine Plate after Covering for 2 Years

The steel structure is easy to be corroded when glass plate is covered with interior scenes. There is no metal component in the closed pool.

Membranes used in membrane system were collected and analyzed thoroughly before use and installation.

These experiments confirm that building membranes are completely suitable for wastewater treatment environment. At the same time, manufacturers analyzed the damage and aging effects of chemicals on membrane materials.

Experiments include:

(一) immersing in different aqueous solutions of NH3 and H2SO4 for a long time;

(二) Testing changes in tensile strength before and after immersion to assess changes in mechanical properties of fabrics;

(三) Anti-hydrolysis: strictly in accordance with NFG37122 (European Standard Hydrolysis Stability Test, NFG37122), after the above anti-corrosion test verification, can provide a detailed anti-corrosion durability report, with 15 years of quality assurance.

Safety of membrane system

Membrane structure has stronger resistance to load. The common structural loads are self-weight, wind load, snow load and earthquake action.

(1) The self-weight of light fluorocarbon fibre membranes is generally only about 1 kg/m2, which belongs to light weight and high strength materials. It is especially suitable for large-span ponds such as sedimentation tanks, which minimizes the influence of the self-weight load of covering materials. In addition, a large number of purlins are needed to support the sunshine plate and FRP, and the membrane is a material reflecting the structural behavior through pre-tension, so it can achieve a large span without any supporting rods in the middle, so the weight of steel members is greatly reduced.

(2) The shape of the membrane system is mostly conical, and because of the requirement of gas collection, the wind will slip through the membrane surface of the curve. Referring to the "Code for Load of Building Structures", the figure coefficient of the membrane system is 0.5-0.8, and the data of wind tunnel tests are smaller, which weakens the influence of wind load on the structure. The Shengxiong leather industry sewage tank in Wenzhou area adopts steel-supported anti-suspension membrane structure. It has just experienced the strongest typhoon of this year, Sea anemone. Its structure is intact and intact, which fully reflects its wind resistance advantages.

(3) Snow-loaded fluorocarbon fibre membrane structure belongs to tension system. It is necessary to form a relatively large negative Gauss hyperboloid in order to effectively apply prestressing force. Therefore, the membrane surface must have a large height difference, that is, a relatively large slope can be formed. In addition, the surface of the film is very smooth, which makes it difficult for snow to accumulate on the film surface. The snow cover coefficient can be selected according to the height difference according to the "Code for Load of Building Structures", and skiing test can be done on its own.

(4) Seismic action (live load) is very small because the membrane weight is small, and the structure belongs to flexible system, and the natural vibration period is long. According to the formula of seismic inertia force I(t)=-m[?G(t)+?(t)], it can be seen that when the mass m is small and the natural vibration period T is large, the seismic action is very small, so the influence of seismic action can be greatly reduced.

(5) Service life of structural design: It can be designed according to 2 or 3 categories in the Unified Standard for Reliability Design of Building Structures (GB50068). The safe service life can be considered by referring to the three-level durability life in the General Principles of Civil Architectural Design, even if the service life is 25-50 years. The structural design and construction company can also produce load/internal force calculation certificates and other calculation certificates according to the design requirements. Ensure the safety and stability of the structure in theory.Material data comparison of covering materials Sunshine panels are polycarbonate hollow panels, which are processed from high performance engineering plastics - Polycarbonate (PC) resin.

The physical and mechanical properties of the sheet are as follows:

|

Entry name |

Unit |

Sheet thickness |

Index value |

Remarks on Test Method (ASTM) |

|

specific gravity |

g/cm3 |

1.2 |

D-792 |

|

|

Impact strength (Izod, notch) |

J/m |

>850≥≥ |

D-256 |

|

|

Tensile yield strength |

MPa |

≥60 |

D-256 |

|

|

Tensile fracture strength |

MPa |

≥70 |

D-638 |

|

|

Elongation at yield |

% |

≥6 |

D-638 |

|

|

Elongation at break |

% |

>100 |

D-638 |

|

|

Compressive strength |

MPa |

>75 |

D-695 |

|

|

Modulus of elasticity |

MPa |

2400 |

D-638 |

|

|

Coefficient of thermal expansion |

1/oC |

6.7×10-5 |

D-696 |

|

|

Thermal conductivity |

W/m·K |

0.2 |

D-177 |

|

|

Thermal Deformation Temperature (Load 1.81 MPa) |

℃ |

135 |

D-648 |

|

|

Drop hammer impact strength |

J |

6mm |

2.1 |

Transparency (colourless transparent plate) |

|

8mm |

2.0 |

|||

|

10mm |

2.44 |

|||

|

Transparency (colourless transparent plate) |

% |

4mm |

82 |

(ASTM D-1003) |

|

6mm |

80 |

|||

|

8mm |

80 |

|||

|

10mm |

79 |

|||

Glass sheet material composition: unsaturated polyester resin, glass fiber base cloth, initiator, additives, pigments paste, etc. The thickness of FRP ranges from 3 mm to 7 mm.

|

Physical properties of FRP |

|||

|

Serial number |

Items |

Index |

Standard |

|

1 |

Water absorption rate |

<0.5 |

GB1462-78 |

|

2 |

impact strength KJ/㎡ |

>5 |

GB1451-83 |

|

3 |

bending strength Mpa |

>150 |

GB1449-83 |

|

4 |

Flexural modulus of elasticity Mpa |

>7000 |

GB1449-83 |

|

5 |

tensile strength Mpa |

>100 |

GB1447-83 |

|

6 |

Tensile Weak Modulus Mpa |

>7000 |

GB1447-83 |

|

7 |

Barcol hardness |

>35 |

GB3854-83 |

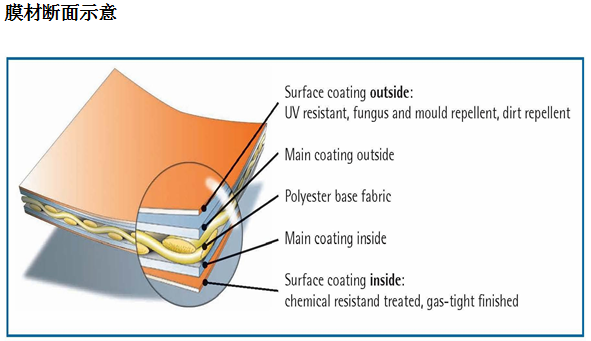

High tension warp and weft polyester filaments provide high strength structural properties for the mechanical part of membrane material structure.

Polymer surface treatment provides acid and alkali resistance for anticorrosive parts of materials.

PVDF coating is the appearance part of the material for surface treatment, providing self-cleaning performance.

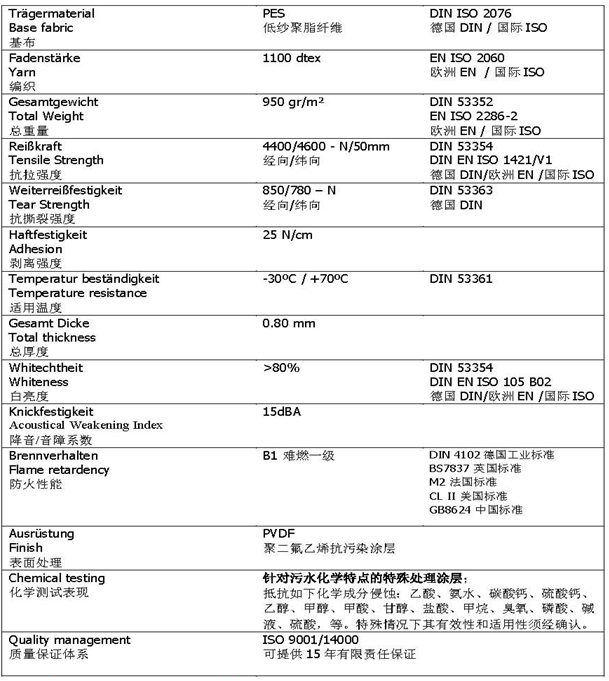

Physical properties of membranes

|

Items |

Data value |

Test method |

|

Weight |

1050(g/m2) |

NF EN ISO2286-2 |

|

Thickness |

0.8 ~1(mm) |

NF EN ISO2286-2 |

|

Tensile Strength (Longitudinal/Weft) |

4400~5500(kn/5cm) |

NF EN ISO1421 |

|

Tear strength (longitudinal/transverse) |

500 (kn/5cm) |

DIN 53-363 |

|

Fire test |

PASS |

NFPA 701 |

|

Transmittance |

6% |

ASHRAE 74-1988 |

|

reflectivity |

78% |

ASHRAE 74-1988 |

Membrane Technical Data

Comparison of Economic Performance of Several Covered Structures

|

Capping structure |

Service life |

Span of use |

Cost of steel structure |

Covering material cost |

|

Common Carbon Steel Framework (Inside)+Sunshine Plate (Outside) |

2~4years |

Within 10 meters |

200~250 |

100~150 |

|

Common Carbon Steel Framework (Embedded)+Glass Plate (Outside) |

More than 5~6 years |

Within 8 meters |

Around 250 |

200~300 |

|

Stainless steel skeleton (inside)+toughened glass (outside) |

More then 8~10years |

Within 15 meters |

800~1000 |

250~500 |

|

Common carbon steel skeleton (outer side)+membrane system (reverse suspension) |

More than 15years |

Within 70 meters |

280~350 |

350~450 |

-

Application of Membrane Structure in Rail Transit...

Application of Membrane Structure in Rail Transit... -

Application of Thermal Insulation Lining Technology in Membrane Archit...

Application of Thermal Insulation Lining Technology in Membrane Archit... -

Application of membrane curtain wall...

Application of membrane curtain wall... -

Application of Membrane Roofing...

Application of Membrane Roofing... -

Application of Membrane Structure in Environmental Protection Engineer...

Application of Membrane Structure in Environmental Protection Engineer... -

Application of Membrane Structure in Sewage Treatment Plant...

Application of Membrane Structure in Sewage Treatment Plant...